As specified by IS3043 – Code of Practice for Earthing, the conduction in an earth electrode is not ohmic but electrolytic in nature. Hence the performance of an earth electrode mainly depends on the resistivity of the soil (electrolyte) surrounding the earth electrode. The philosophy of Earthing is that “Lower the Resistivity of Soil, Better the performance of Earthing but Lower the resistivity of soil, higher will be the corrosion rate which results in shorter life time of the earthing system.

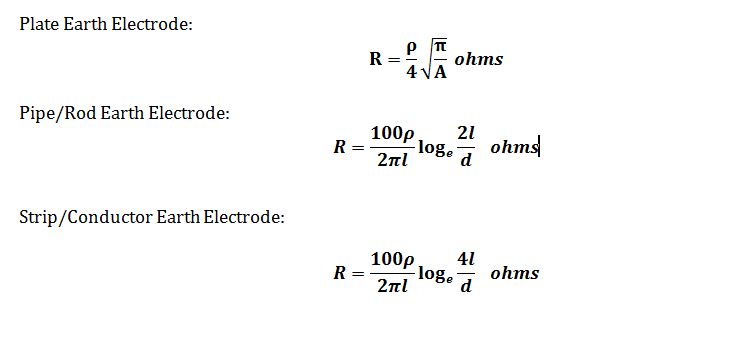

The formula provided by IS 3043 for calculating the earth electrode resistance values are as follows:

The earth electrode resistance depends on the soil resistivity and the dimensions of the earth electrodes. The ohmic resistance value of the material is not considered for the earthing design calculations and hence the kind of metal plays a role only in enhancing the life time of the earthing system and not the performance of the system. Hence it becomes extremely important to choose the right kind of electrode with appropriate dimensions mentioned in the IS standard for your earthing system for a long lasting performance, for which it is important to understand the characteristics of each metal to be used as Earth Electrode.

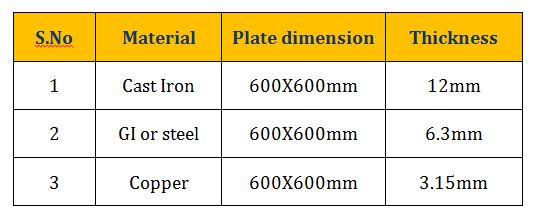

Most of the people believe that copper is commonly used as earth electrode because of its very low resistance value. But the actual reason for preferring copper for earth electrode is its high corrosion resistance property. IS 3043 under Clause 14.2.1 explains the thickness of different materials for being used as plate earth electrode and the details are as follows,

Under clause 14.3- Selection of metals for earth electrodes, IS 3043 explained about the corrosion rates of different materials buried in different soil conditions.

Sample dimension: 150X25X3mm

The average loss in weight of specimens of different materials buried on different soil conditions is listed below.

The corrosion rate of cast iron material is higher than that of copper and GI and hence if we go for cast iron material then the thickness of cast iron should be greater.

As few of them spoke about copper bonded rods/pipes as being earth Electrode, we as a manufacturer & services provider would like to throw some light on the same as well. Copper bonded rods are viable to be used as earthing electrodes, provided high quality standards are maintained while bonding the copper on the surface of the Mild Steel rods/pipes. Copper bonded earth electrode configurations are prescribed by the following standards.

If high quality standards and processes are not adhered to, there is a high chance of copper getting peeled off from the electrode over a period of time leaving the mild steel rods exposed to corrosion. UL 467 an international standard followed by various countries as a benchmark for producing high quality copper bonded rods prescribes a strict quality process of manufacturing such rods to ensure the life of the electrode does not diminish earlier than the expected time frame. Some of the tests carried out by the UL as quality standards are

Conclusion:

As the resistance of an earth electrode doesn’t depend on the material, the selection of the material mainly depends on the local site conditions, life expectancy, and financial feasibility of the particular project.