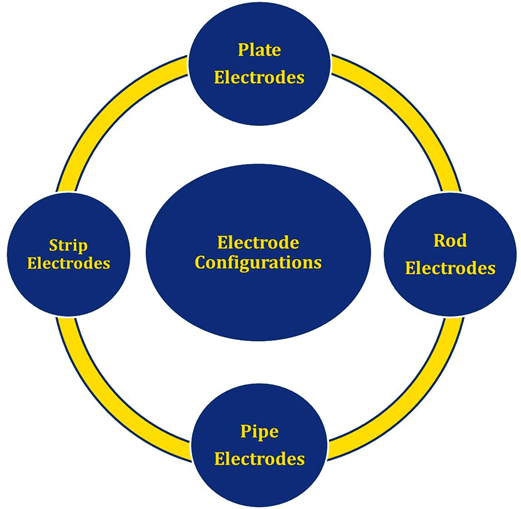

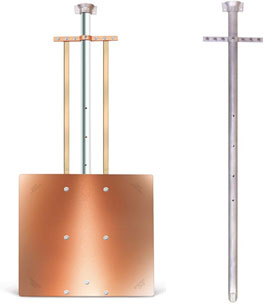

Providing a low resistance path to the ground for the fault currents to ensure the safety of the operating personnel and the equipments is earthing. It comprises of an earth electrode, earth enhancing compound and a terminal connector.

As mentioned by IS 3043, the conduction of current in an earthing system is electrolytic in nature and the soil surrounding the earth electrode acts as electrolyte. Hence the Earth Resistance of an electrode is made up of the following factors:

Earth enhancing compound is a highly conductive and anti-corrosive compound filled around the earth electrode to enhance the faster dissipation of fault currents into the ground.

In areas with soils of high resistivity, multiple earth rods in parallel connection may fail to produce an adequately low resistance to earth value. The alternative way for reducing the earth resistance value is to reduce the resistivity of the soil immediately surrounding the earth electrode as the major part of the fall in potential occurs closer to the electrode surface. Hence, using highly conductive earth enhancing compounds around the earth electrode is an effective way of achieving low earth resistance value.

Since the materials are directly exposed to the environment, the impact of these materials is very high and it may pollute the land and groundwater. Hence, special care should be taken in selecting the materials for Earth Enhancing Compounds. The materials should have the following characteristics.

CARBOLITE is best suited Earth Enhancing compound for normal and moderate soil conditions. It contains various natural minerals which are anti corrosive and highly conductive mixed together and made into powdery form to be used around the earth electrode to increase the efficiency of the earthing system.

CARBOTITE is an earth enhancing compound made specially for high resistive soil conditions. It contains 70% of carbon in it to bring down the resistivity around the electrode to minimum.